Wireless connectivity is becoming more common in enterprise networks, improving performance in more ways than one, and changing how people work. As businesses increasingly rely on reliable connections, secure data access, and on-demand communication, the Panduit Fault Managed Power System (FMPS) emerges as a game-changer. This Class 4 power system is the first in the market to comply with the new UL 1400-1 Standard, offering a safer, more reliable, and easy-to-install power delivery system that provides substantial time and cost savings.

Navigating Power Distribution Complexities

Miller Electric Company, a leading electrical and technology solutions contractor and long-standing Panduit Partner, recently faced a complex power distribution challenge. Tasked with the installation of new cameras, distributed UPSs, PoE switches, and media converters across several buildings, Miller Electric encountered an unexpected hurdle. The nearest power source for these new devices was over 1000 feet away, significantly complicating the deployment. The cost and complexity of installing new panels, conduit pathways, and managing power shutdowns made this project far more demanding than initially anticipated.

Collaborating for the Perfect Solution

Recognizing the need for an innovative approach, Miller Electric, known for its expertise in technology solutions, turned to the Panduit Fault Managed Power System. The FMPS system emerged as the ideal solution to address the project's challenges. Along with the UL-Certification, our trusted commitment to customer support stood out throughout the project and our robust network offerings made a complete power distribution solution including Panduit UPSs and PDUs, copper and fiber patch cables and connectivity, racks and cable management, and a host of electrical and grounding accessories.

“When we started looking, the Panduit Fault Managed Power System came up. Panduit and Miller Electric have maintained a partnership for many years. It made perfect sense that we partnered with them for this project too. The most compelling factor that drove this decision was that it is UL-certified. That was huge because that gives me the confidence to install a system which I know is vetted, tested, and approved to GP meet that standard.”

-Chris Cuyler, Senior Project Manager at Miller Electric

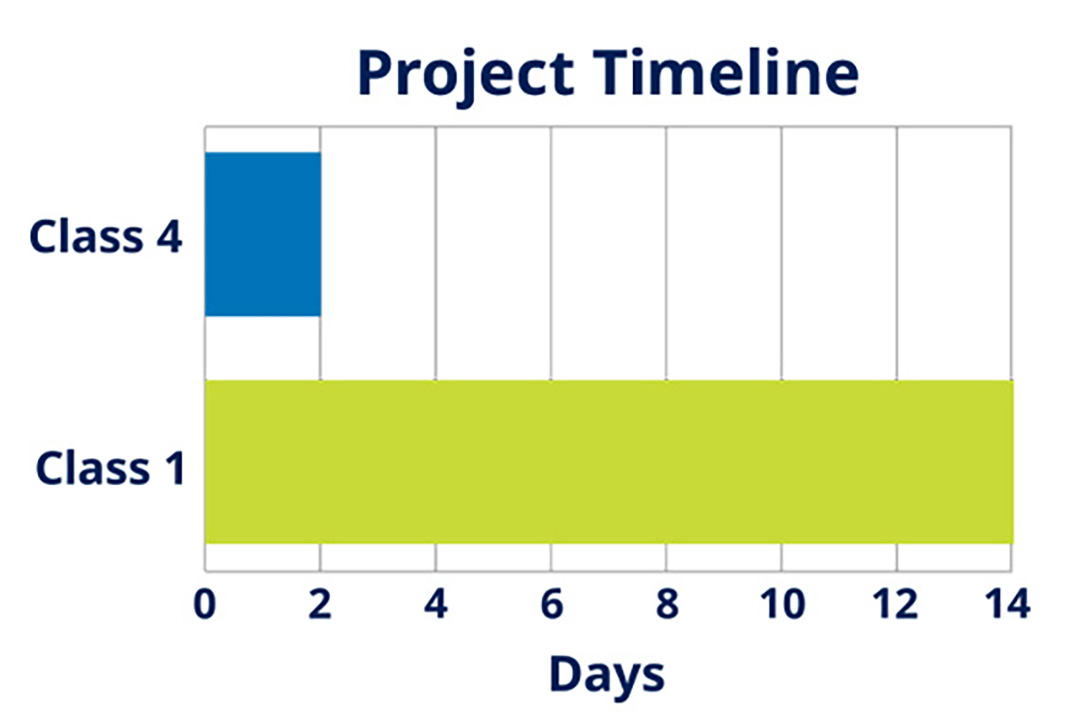

By using FMPS to distribute power across each 85,000 sq. ft. building, Miller Electric was able to complete the project with minimal shutdowns. Even more impressively, the project timeline was reduced from two weeks to just two days.

Seamless Integration and Efficiency

In addition to completing the complex project in less than half the estimated time, the FMPS system proved to have a seamless integration process. Its efficiency allowed the project’s deployment to move forward smoothly and reduce project costs. The integration of FMPS with Avigilon cameras effectively addressed the challenge of powering high-resolution cameras over long distances. This was particularly crucial for cameras on a flight line at an airfield, where the end user required cameras on a thousand-foot building, despite the Ethernet standard being 100 meters. With FMPS, Miller Electric was able to extend power to high-resolution Avigilon cameras across vast distances. The system enabled the installation team to run copper and fiber cables simultaneously, significantly reducing installation time and complexity with minimal shutdowns, thus preventing disruptions to operations.

Discover how the collaboration between Panduit and Miller Electric led to an innovative solution that resolved a complex challenge by reading the full case study.