Ask an Expert: Featuring Seamus Hamrin, Product Manager, Fiber Optic Solutions

Welcome to our "Ask an Expert" blog series, where Panduit product leaders answer the most common customer questions. This week, we spoke with Seamus Hamrin, Product Manager for Fiber Optic Solutions, about OmniSplice™ — Panduit's game-changing fusion-spliced fiber optic cable connector that simplifies fiber termination without compromising performance.

"OmniSplice was built for the field. We wanted to eliminate the complexity that slows down installers, while still delivering lab-grade results."

— Seamus Hamrin

Q: What is OmniSplice?

Seamus: OmniSplice is our pre-polished, fusion-spliced fiber optic connector. It's available in LC & SC formats, for both Singlemode and Multimode (OM3/4/5), including LC-APC and SC-APC variants. It represents Panduit's entry into the fusion-spliced connector space and addresses the growing demand for fast fiber termination.

Q: How does it work?

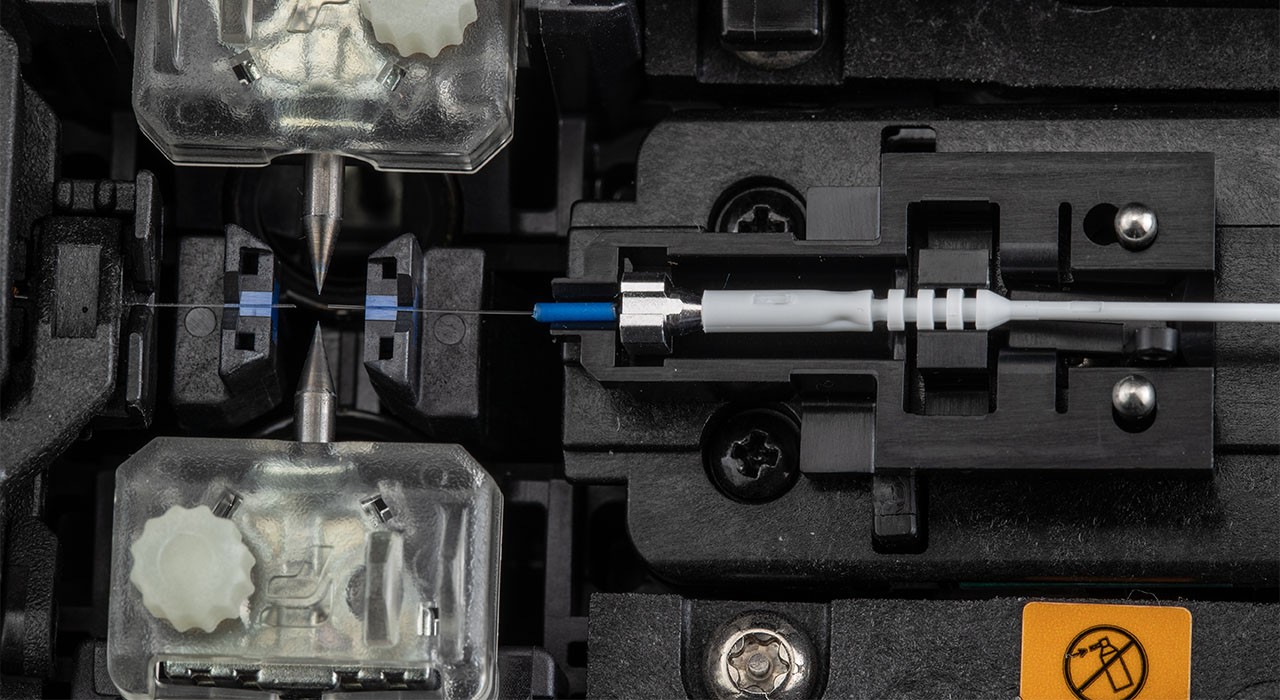

Seamus: The connector subassembly comes pre-polished and pre-cleaved. You place it into the OmniHolder, splice it directly to the fiber cable, then complete the assembly around the splice point. It’s fast, familiar to installers, and backed by Panduit's quality standards.

Q: What makes OmniSplice better than cam-style mechanical connectors?

Seamus: Speed and performance. You can terminate in under two minutes—that’s not theoretical, it’s based on internal time-on-task testing by our engineering team. We consistently see insertion loss well below 0.10 dB. That’s hard to match with cam-style connectors.

Q: How does it compare to fusion splicing pigtails?

Seamus: With pigtails, you need slack management and extra protection hardware. OmniSplice protects the splice inside the connector body, cutting out the need for splice holders or cable management accessories. It’s cleaner, quicker, and more compact, offering better efficiency for field fiber optic terminations.

Q: What types of fiber cable are compatible?

Seamus: It works with 900μm tight-buffered fiber, 250μm loose-tube fiber, and 250μm fibers with 900μm build-up tubing. So, if you're using fanout kits, you're covered.

Q: What fiber optic splicing machines are supported?

Seamus: The OmniHolder supports most current fusion splice machines from Sumitomo, AFL (Fujikura), Fiber Fox, and UCL Swift. That means you can use OmniSplice with the tools you already have in the field.

Q: Is it compatible with other fiber components?

Seamus: Absolutely. OmniSplice fiber cable connectors are fully compliant with applicable standards, ensuring compatibility with other components in your fiber optic network.

Q: How is the product packaged?

Seamus: Each connector is packaged in a recycled plastic tray and shipped in a corrugated cardboard box to reduce single-use packaging waste. Sustainability was part of the design process from the beginning.

Q: Where is OmniSplice most commonly used?

Seamus: OmniSplice is ideal for data centers and enterprise telecommunications rooms where fast, clean, and consistent fiber terminations are critical. It offers a professional-grade solution that supports high-performance networks without requiring additional hardware or complex setup.

Featured Expert

Seamus Hamrin

Product Manager, Fiber Optic Solutions